GEA Hilge SIPLA

Ideal for tank emptying and CIP return processes

The SIPLA pump series enables product and CIP liquid to be pumped with just one pump. Thanks to its outstanding quality and design, which has been carefully considered in every detail, it shows maximum reliability in a wide range of applications in the beverage, food and pharmaceutical industries.

The pump's good suction performance ensures shorter process times, even for media with a high gas content.

Robust and reliable side channel pumps

The pumps of the GEA Hilge SIPLA series are characterized by their particular robustness. The all stainless-steel construction of the pumps' hydraulics exemplifies GEA’s commitment to quality and efficiency. These self-priming pumps have a long service life even under the toughest operating conditions.

Flexible solutions even for specialized applications

The SIPLA series offers a wide variety of connections, diverse sealing options and variable setups for ideal adaptation to individual customer needs and demanding conveying tasks.

The ability to operate in both - clockwise and counterclockwise - directions ensures a high degree of process flexibility.

Additional usage options for several applications with only one pump are provided by a transportable solution as a mobile pump.

GEA Hilge Fast Track Program – We give you priority

For emergencies or when fast delivery within two days is required, we have developed the GEA Hilge Fast Track program. Each pump within the program is ready to ship in 2 days, guaranteed! Here you can find the models and

A wide variety of sealing options are available for customers to choose from

The use of non-porous and blowhole-free materials makes GEA Hilge SIPLA-HT pumps especially suitable for use in the pharmaceutical and biotech industries.

All wetted parts are made of milled stainless steel with a surface finish of Ra < 0.4µm, a ferrite content of <1% and no cast components are used. Optionally, the SIPLA-HT can be supplied as a fully residual drainable version. The robust high-precision design with optimized hydraulic layout for good efficiency and extremely high-quality materials guarantees high operational reliability.

The patented Adapta design allows quick and easy motor replacement, where the pump can remain in the pipeline. Thus, revalidation of the system after an engine change is not necessary for pharmaceutical applications.

The SIPLA pump series enables product and CIP liquid to be pumped with just one pump. Thanks to its outstanding quality and design, which has been carefully considered in every detail, it shows maximum reliability in a wide range of applications in the beverage, food and pharmaceutical industries.

The pump's good suction performance ensures shorter process times, even for media with a high gas content.

Robust and reliable side channel pumps

The pumps of the GEA Hilge SIPLA series are characterized by their particular robustness. The all stainless-steel construction of the pumps' hydraulics exemplifies GEA’s commitment to quality and efficiency. These self-priming pumps have a long service life even under the toughest operating conditions.

Flexible solutions even for specialized applications

The SIPLA series offers a wide variety of connections, diverse sealing options and variable setups for ideal adaptation to individual customer needs and demanding conveying tasks.

The ability to operate in both - clockwise and counterclockwise - directions ensures a high degree of process flexibility.

Additional usage options for several applications with only one pump are provided by a transportable solution as a mobile pump.

GEA Hilge Fast Track Program – We give you priority

For emergencies or when fast delivery within two days is required, we have developed the GEA Hilge Fast Track program. Each pump within the program is ready to ship in 2 days, guaranteed! Here you can find the models and

A wide variety of sealing options are available for customers to choose from

- Single mechanical seals in sterile execution Flushed mechanical seals

- Standard seal face material: carbon/stainless steel and SiC/SiC

- Standard O-ring material: EPDM or Viton

- Additional designs and materials available upon request

The use of non-porous and blowhole-free materials makes GEA Hilge SIPLA-HT pumps especially suitable for use in the pharmaceutical and biotech industries.

All wetted parts are made of milled stainless steel with a surface finish of Ra < 0.4µm, a ferrite content of <1% and no cast components are used. Optionally, the SIPLA-HT can be supplied as a fully residual drainable version. The robust high-precision design with optimized hydraulic layout for good efficiency and extremely high-quality materials guarantees high operational reliability.

The patented Adapta design allows quick and easy motor replacement, where the pump can remain in the pipeline. Thus, revalidation of the system after an engine change is not necessary for pharmaceutical applications.

GEA Hilge SIPLA Adapta/GEA Hilge SIPLA-HT Adapta: Close-coupled pump with bearing bracket and coupling, horizontal installation

GEA Hilge SIPLA Adapta-SUPER/GEA Hilge SIPLA-HT Adapta-SUPER: Close-coupled pump with bearing bracket and coupling, horizontal installation, motor with stainless steel shroud

GEA Hilge SIPLA Bloc: Close-coupled pump, horizontal installation

GEA Hilge SIPLA Bloc-SUPER: Close-coupled pump, horizontal installation, motor with stainless steel shroud

GEA Hilge SIPLA tronic/GEA Hilge SIPLA -HT tronic: Motor with built-in frequency converter (horizontal/vertical installation)

GEA Hilge SIPLA Adapta-SUPER/GEA Hilge SIPLA-HT Adapta-SUPER: Close-coupled pump with bearing bracket and coupling, horizontal installation, motor with stainless steel shroud

GEA Hilge SIPLA Bloc: Close-coupled pump, horizontal installation

GEA Hilge SIPLA Bloc-SUPER: Close-coupled pump, horizontal installation, motor with stainless steel shroud

GEA Hilge SIPLA tronic/GEA Hilge SIPLA -HT tronic: Motor with built-in frequency converter (horizontal/vertical installation)

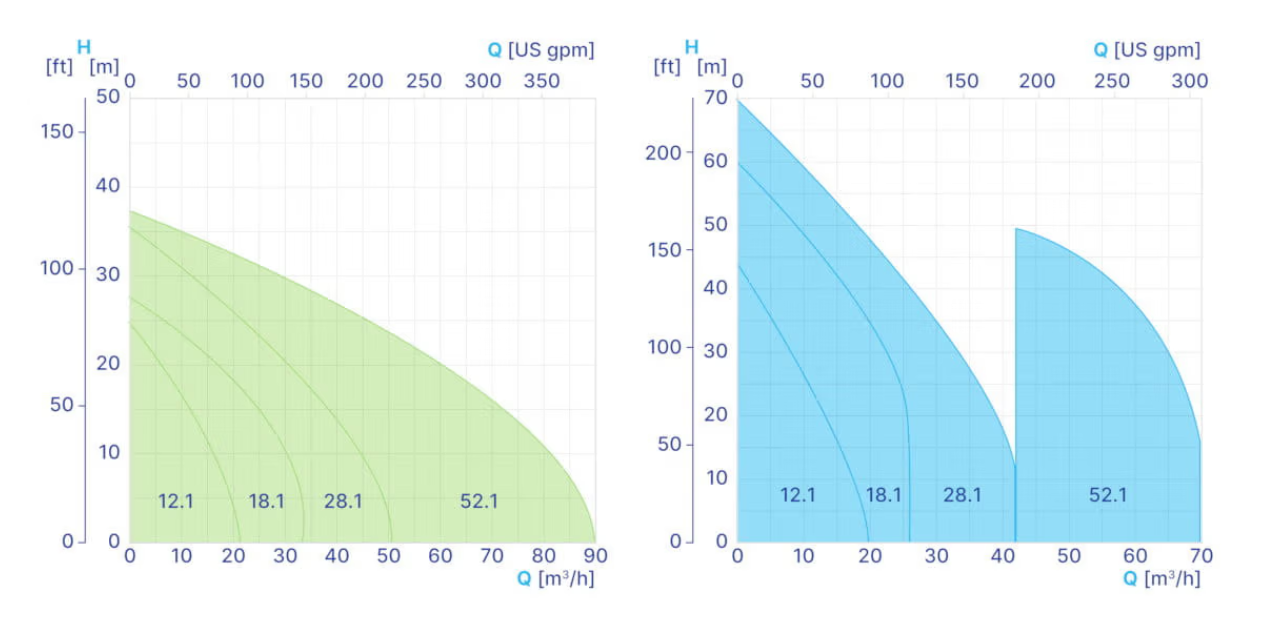

GEA Hilge SIPLA 50 Hz

Flow: 80 m³/h

Head: 50 m

Operating temperature: 95 °C

Sterilization temperature: up to 140 °C (SIP)

Operating pressure: PN 10

GEA Hilge SIPLA 60 Hz

Flow: 65 m³/h

Head: 60 m

Operating temperature: 95 °C

Sterilization temperature: up to 140 °C (SIP)

Operating pressure: PN 10

Flow: 80 m³/h

Head: 50 m

Operating temperature: 95 °C

Sterilization temperature: up to 140 °C (SIP)

Operating pressure: PN 10

GEA Hilge SIPLA 60 Hz

Flow: 65 m³/h

Head: 60 m

Operating temperature: 95 °C

Sterilization temperature: up to 140 °C (SIP)

Operating pressure: PN 10

GEA Hilge SIPLA

GEA Hilge SIPLA-HT