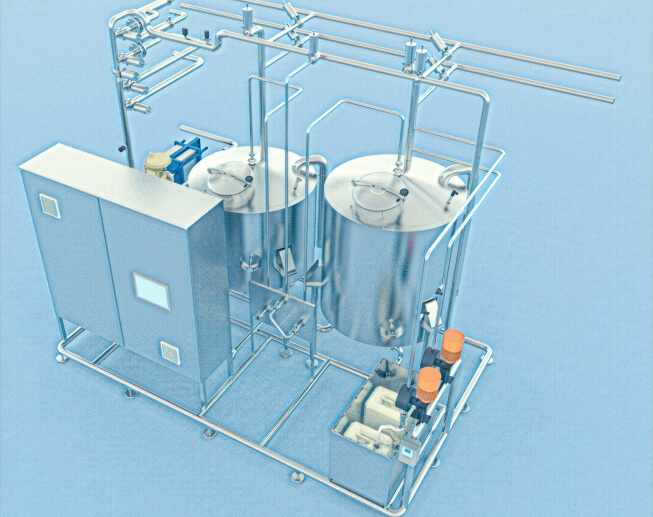

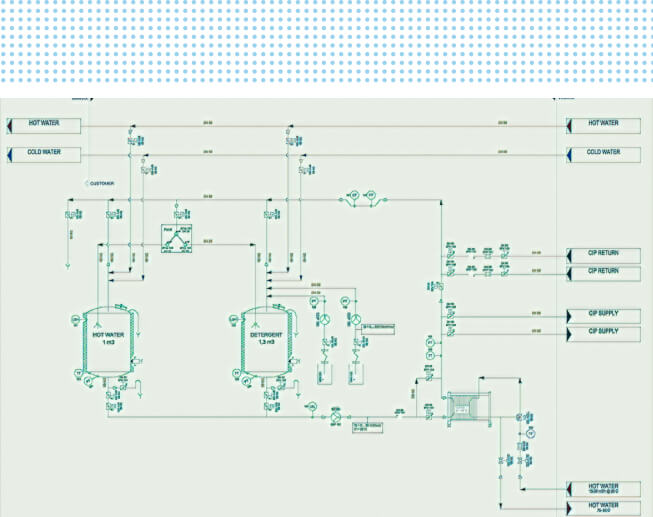

Unit has 2 tanks each is supplied with:

- manhole for checks and service;

- spray ball for self cleaning;

- top and bottom level sensors;

- level meter that controls level in each tank;

- temperature sensor;

- hygienic sampling valve (Keofitt, Alfa Laval or similar);

- 2 lines for hot and cold water.

- 2 lines for dosing of cleaning products (concentrates) that has automatic valves, 2 membrane pumps and pressure transmitters.

- centrifugal pumps with frequency drives;

- flow meters;

- Ph meters;

- temperature sensors

- heat exchangers with control valves for steam or hot water;

- filters;

- process and control valves.

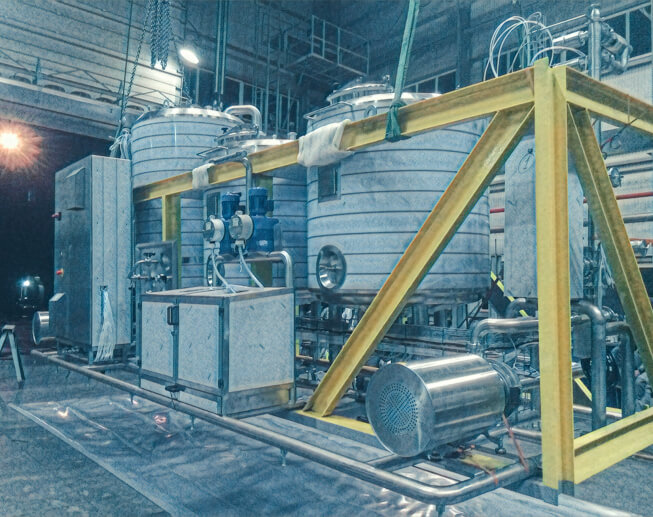

Viravix Engineering offers a turnkey CIP washing for the dairy industry. Our specialists will carry out the entire cycle of work: from the design of the station to commissioning, with subsequent warranty service.