16.07.2024

Monitoring systems for breweries

Why do you need monitoring systems?

Remote monitoring of production processes helps:

- monitor key parameters around the clock and respond quickly to abnormal situations;

- objectively see bottlenecks in production and find ways to improve the process;

- reduce equipment downtime due to emergencies;

- plan effectively the repair and investment programme based on the actual condition of the equipment

- to see the places of leaks and losses, to reduce costs for energy and water consumption;

- receive objective reporting on the state of the brewery.

The customer receives a financial benefit that exceeds the investment in online monitoring of production lines.

Examples:

- In Viravix’s practice, remote monitoring of production parameters helped to increase the productivity of the fermentation section by 15% without costly upgrades. The system saw that the separation equipment was under-utilised due to the existing process layout.

- A day’s visit to the brewery by an expert costs around 340 euros in travel expenses. With the implementation of remote production monitoring, he can solve the customer’s problems remotely, without being present at the brewery in person. The system will provide all the data for analysis.

What you can monitor in the brewery

Fermentation tanks (CCT)

Monitoring the temperature and pH during the fermentation and filtration processes helps to ensure efficient wort extraction

Boiling

Temperature and volume monitoring ensures that the wort is boiled for the right amount of time to achieve the desired level of flavour and bitterness

Fermentation

Temperature and pressure monitoring makes sure that the yeast works optimally and delivers the required alcohol level

Carbonation

Temperature and carbonation level monitoring helps to monitor the maturation of the beer and guarantee the flavour profile of the recipe

Packaging

Tracking the consistency and quality of the filling process ensures that the requirements of the finished product are met

The list of applications for remote monitoring of production line processes in a brewery is open. The installation and configuration of the system depends on the customer’s needs. You can also monitor pasteurisation, CIP washing, energy and water consumption.

Monitor your brewery 24/7 from anywhere in the world where the internet is available.

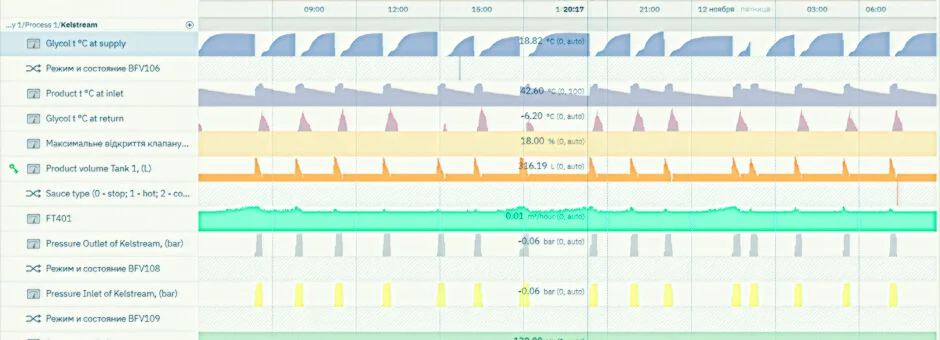

Examples of monitoring systems for different equipment

A hardware and software system consists of sensors, controllers and software with a user interface. The detectors can be installed on almost any equipment, and the setup of the system is similar to that of Wi-Fi.