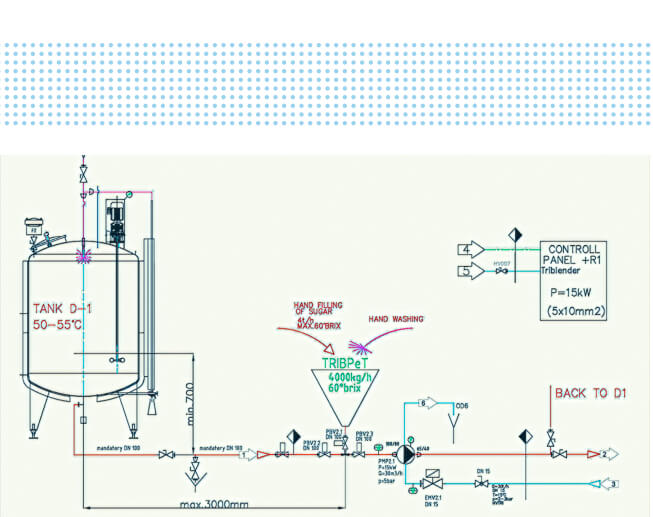

Main components of station are:

- Centrifugal pump (for circulation) supplied with flashing of bearings;

- Seat valve for flow control;

- Automatic leak proof control valve;

- Automatic and manual butterfly valves;

- Non-return valve;

- Mesh filter;

- Sight glass.

- Inductivity sensor;

- Temperature sensor;

- Pressure sensor;

- Flowmeter.

- Spray balls of CIP;

- Vertical mixer;

- Manhole;

- Top and bottom level sensors;

- Level meter;